1050 Aluminum Sheet

- Home

- 1050 Aluminum Sheet

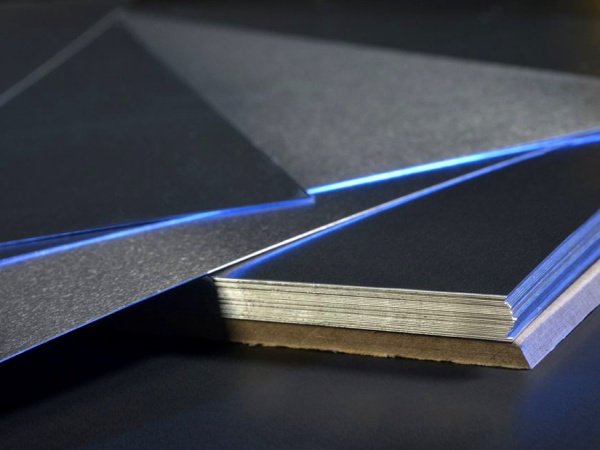

1050 Aluminum Sheet

Aluminum plate of 1050 contains more than 99.5% aluminum, is a kind of industrial pure aluminum. 1050 aluminum plate has the characteristics of high plasticity, corrosion resistance, good electrical and thermal conductivity, but the strength is low. Commonly used in some occasions that require high corrosion resistance and form-ability, but the strength is not high.

Application Of 1050 Aluminum Sheet

- Daily necessities

- Lighting appliances

- Reflectors

- Decorations

- Chemical industry containers

- Heat sinks

- Signs

- Electronics

- Lamps

- Nameplates

- Electrical appliances

- Stamping parts,etc

Feature Of 1050 Aluminum Sheet

Its characteristics are that it contains more than 99.00% aluminum, has good electrical conductivity, good corrosion resistance, good welding performance, low strength and cannot be strengthened by heat treatment.

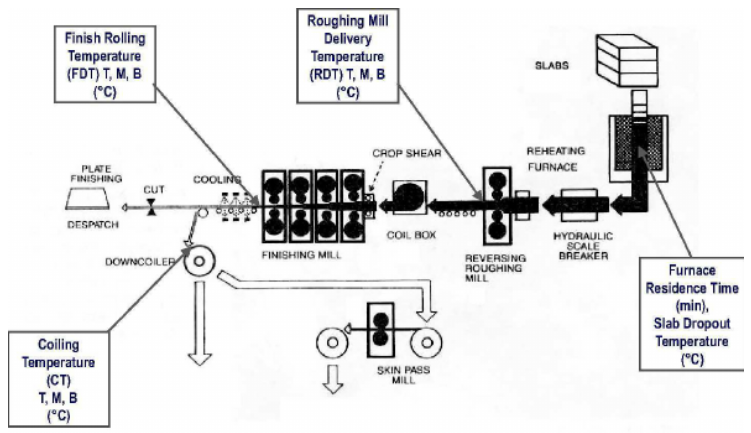

Processing Line(CC)

- Taking the aluminum ingots and little scrap into the melting furnace and melting them into Aluminum liquid.

- Let the Aluminum liquid flow into another furnace to settle the impurity substance, at the same time,add other needed chemical composition to the liquid.

- Aluminum liquid is directly pour into continue casting machine and transformed into the mother coils about 500mm in thickness.

- After being polished and cleaned, the slabs will be conveyed to hot rolling processing line, heating and softening. Then they will enter into the line and rolled into mother coils 6-10mm in thickness.

- Sending the mother coils to cold rolling line and planishing them to the needed thickness.

- Annealing them in the annealing oven.This process can change the coil’s physical performance, such as the tensile strength, yield strength and elongation. The time and times is different in different grades.

- After being cooled down, the coils will enter into the tension leveler machine. The process is to clean the coil and ensure their good planeness. It is available just for the coils less than 2.0mm in thickness, if not, they have to be cleaned in the washer by hot water.

- If necessary, a final annealing operation can performe again.

- Cutting the coils into needed length.

- We strictly according to the international standard to package, use EPE to protect the aluminum sheet, the plastic sheet is to proof water, the carton to prevent from being hit, the steel bar can make it more stable. And every package will put the desiccant.

- Sending them to storage.

Specification

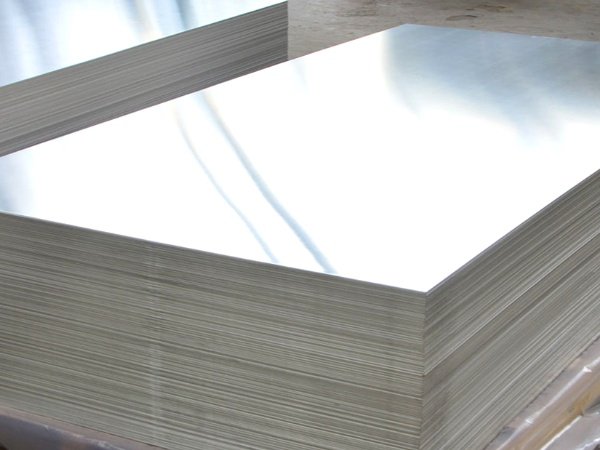

| Name | Mill finish aluminum |

| Alloy | 1xxx,3xxx,5xxx,6xxx,8xxx series |

| Temper | O,H14,H16,H18,H24,H26,H116,etc |

| Thickness(mm) | 0.2-100mm |

| Width(mm) | 10-2700 |

Chemical composition and properties

Aluminum Al: surplus

Silicon Si: 0.25

Copper Cu: 0.10

Magnesium Mg: 2.2 ~ 2.8

Zinc Zn: 0.10

Manganese Mn: 0.10

Chromium Cr: 0.15 ~ 0.35

Tensile strength (σb) : 170 ~ 305MPa

Conditional yield strength σ0.2 (MPa)≥65

Elastic modulus (E) : 69.3 ~ 70.7Gpa

Annealing temperature: 345℃.

Cleaning steps of 1050 aluminum plate

- Rinse the surface of the plate with a lot of water

- Gently wipe the surface of the test board with a soft cloth soaked with detergent diluted with water

- Then wash the board with a lot of water, wash away the dirt

- Check the surface of the board and clean any places that still have detergent.

- Rinse the board with clean water until the detergent wash away

- Note: Do not clean the hot surface (temperature over 40 °C), because the moisture volatilization is harmful to the surface paint!

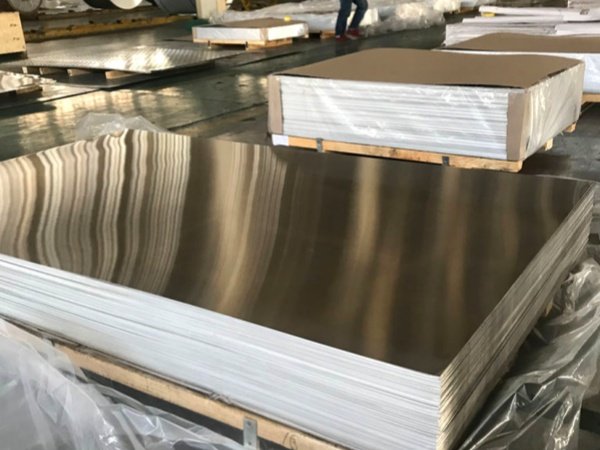

1060 Aluminum Sheet

Aluminum sheet of 1060 has high elongation, tensile strength, excellent electrical conductivity, high formability, can fully meet the conventional processing requirements (stamping, stretching) requirements.

Various industries often use 1060 aluminum plates for lithium battery soft connections, bus bars, road signs, charging piles, aluminum gaskets, billboards, building appearances, high-rise appearances, factory appearances, office cubicle decorations, lamp holders, fan blades, electronic parts, kitchen utensils, reflective appliances, and more. With aluminum foil, etc.