Aluminum Honeycomb Panel

Aluminum honeycomb panel has become a revolutionary product in the construction industry. These lightweight and durable panels offer a unique combination of strength, versatility and energy efficiency.

| Product | Aluminum honeycomb panel |

| Alloy | 3003, 3004, 5052 |

| Temper | H18 |

| Aluminium foil thickness | 0.03mm-0.15mm |

| Side length | 3mm, 4mm, etc, accept customization |

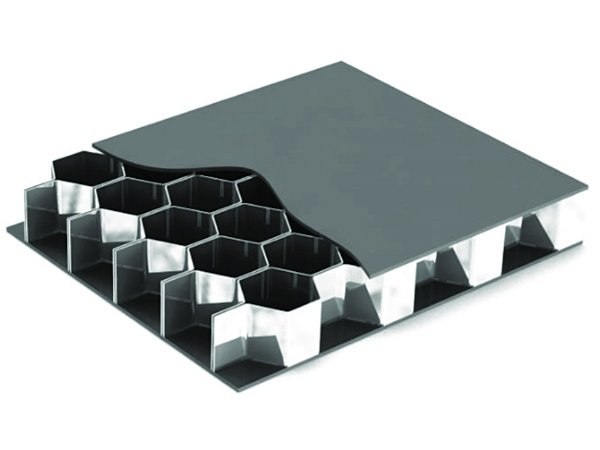

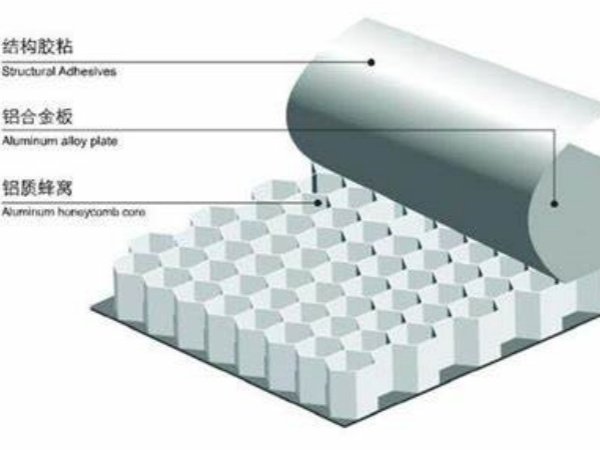

What is aluminum honeycomb panel?

It is a honeycomb sandwich structure as a whole. It is a composite plate made of high-strength alloy aluminum plate as the surface, bottom plate and aluminum honeycomb core through high temperature and high pressure. Aluminum plate surface coating with excellent weatherability of decorative coatings. This kind of plate will greatly enhance the structural integrity of the original aluminum plate, making it less likely to bend. The larger the scale, the better the flatness.

Advantage

- Large surface, high flatness: Without any reinforcement measures, its size can reach 1500*5000mm and can maintain excellent flatness.

- Light weight: Its weight is only 5~5.5kg/square meter, which greatly reduces the load-bearing load of the building.

- High strength: lt can withstand high-intensity pressure and shear force. And it is not easy to deform, and can meet the wind pressure resistance requirements of super high-rise buildings.

- Product customization: size, shape, paint, color, etc.

- Easy to install: It can be installed in any order. And remove the change separately each wallboard, improve the flexibility of the installation and maintenance, reduce the cost.

- Box structure: lt is a box-type structure with edges on all sides, which has good air tightness and improves the safety and service life of the honeycomb aluminum panel.

- No welding, no exposed nails: It uses corner codes and screws to connect, eliminating the need for frame welding, and there are no exposed nails on site after the surface layer is installed, making it clean and tidy.

- Good sound insulation, heat insulation, fire prevention and heat preservation effects: Because the honeycombs are individually closed, they block the circulation of air, effectively blocking sound waves and heat, greatly reducing the sound waves and thermal conductivity of the board, and achieving the effects of sound insulation, heat insulation, and heat preservation. Moreover, aluminum panels are non-combustible and therefore fireproof.

- Various colors: The coating includes fluorocarbon spraying, polyester spraying, etc. The colors are pure color, metallic color, imitation wood grain, imitation stone grain, etc. to make the shape more beautiful.

Application

- Building curtain wall

- Ceiling

- Furniture

- Cut off

- Elevator engineering

- Rail transit

Aluminum honeycomb panel price

Many factors will affect the price, such as aluminum ingot price, thickness, etc. So you can contact us and we will have professional sales staff contact you and give you a quote.

Manufacturing process

Preheat → grind and brush the aluminum plate clean → spray structural adhesive and heat up → lay the honeycomb aluminum core → maintain pressure → cut semi-finished products → dry → bond and install

Surface type

- Solid colorand Metallic color: It is available in PE or PVDF paint, and has a variety of colors for customization.

- Stone grain: The surface of the stone grain aluminum honeycombpanel is not real marble, but a simulated stone grain aluminumhoneycomb panel made of fuorocarbon, stone grain transfer paper andother materials as surface treatment materials.

- Wood grain: Wood grain: It is first sprayed on the surface, and then uses thermal transfer technology to form the pattern.