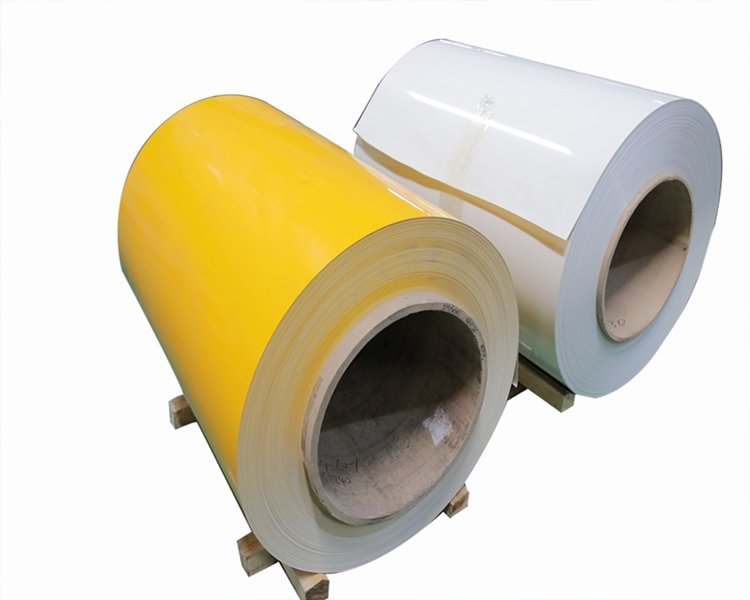

Color Coated Aluminum Coil

Color coated aluminum coil are widely used in aluminum honeycomb panels, aluminum ceilings, roof surfaces and other buildings. This shows how popular it is as a decorative material.

| Product | color coated aluminum coil |

| Alloy | 1060, 3003, 3004, 5052, etc |

| Temper | H14, H24, H22, H46, etc |

| Thickness | 0.02mm-5.0mm |

| Width | 10mm-1850mm |

| Packaging | eye to wall, eye to sky |

| MOQ | 3 tons |

Advantage of color coated aluminum coil

- Flat surface

- Highly decorative

- Good weather resistance

- Light weight

- Corrosion resistant

- Environmental friendly

- Stable performance

- Long shelf life

Application of color coated aluminum coil

- Ceiling

- Gutter

- Roofing

- ACP

- Facades

- Roller Shutter

- Sublimation sheet

- UV Digital Ink Printing

- License plate material

- Truck body material

Classification of color coated aluminum coil

Coating

According to the type of coating, it can be divided into PE color coated aluminum coil and PVDF color coated aluminum coil.

PE

PE is an anti-UV coating. UV absorbers can be divided into matte and high-gloss series according to glossiness. Therefore it is especially suitable for interior decoration and advertising boards.

PVDF

The molecular structure of the PVDF coating is tight and has super weather resistance. Therefore, it is particularly suitable for decoration and display in outdoor decoration, commercial chains, exhibition advertising, etc.

The difference between PE and PVDF

- PE is usually used indoors, and PVDF is usually used outdoors.

- PVDF has a longer shelf life than PE. PE is usually 10 years, while PVDF is usually 15-20 years.

- PVDF price is higher than PE.

- PE can only single-coated or double-coated. PVDF can double-coated and triple-coated.

The same between PE and PVDF

- They can both do solid and metallic colors.

- They can all double-coated.

Coating thickness

single-coated: 16μm-18μm

double-coated: 26μm-28μm

triple-coated: 36μm-38μm

Commonly used alloys

Aluminum has 8 series from 1 to 8, and color coated aluminum coil usually use 1 series, 3 series, and 5 series. Their characteristics and differences are as follows:

1 series: It is pure aluminum. Since it does not contain other alloying elements, the production process is relatively simple and the price is relatively cheap. It is one of the more commonly used materials in color coating. However, because it is pure aluminum, the material is relatively soft. Commonly used alloy is 1060.

3 series: It is an aluminum-manganese alloy. The alloy component is mainly manganese, so it has good anti-corrosion properties. We also call it rust-proof aluminum. Its hardness is higher than Series 1 pure aluminum, and its tensile properties are better than Series 1. It is also one of the most commonly used materials in color coating. Commonly used alloys are 3003 and 3004, but the price is higher than the 1060.

5 series: It is an aluminum-magnesium alloy, the alloy component is mainly magnesium. Its main features are low density, high tensile strength and high elongation. Due to its low density and light weight, it is often used in the aviation field and are called aviation aluminum. They are sometimes used to produce color coated aluminum. In terms of mechanical properties, the 5 series aluminum plate has higher tensile strength than the 3 series aluminum plate, and its performance is also better than the 3 series aluminum plate. Of course, the price is relatively high. Commonly used alloy is 5052.

About us

GUSTO has been engaged in the aluminum color coated coil business for many years. We have the most advanced equipment in the country, so our company is the only company in our province that can produce color coated products with a thickness of 5.0mm and a width of 1800mm. Our color coated products are sold all over the world and receive widespread praise from customers. Welcome to come to us to buy, our sales team will serve you wholeheartedly.