Mirror Aluminum

In life, we can often see mirror aluminum plates. Although their colors, sizes, and shapes are not consistent, it is undeniable that these all demonstrate the wide range of uses and popularity of mirror aluminum plates.

| Product | Mirror aluminum |

| Alloy | 1050, 1060, 3003, 5052, etc |

| Temper | H14, H24, |

| Thickness | as per customer requirement |

| Width | as per customer requirement |

| Color | silver, gold, tea gold,black, etc |

| Delivery time | 20 days |

| MOQ | 3 tons |

What is mirror aluminum?

It generally refers to aluminum plates or aluminum coils that are processed by various methods such as rolling and grinding to give the aluminum surface a mirror effect.

Advantage of mirror aluminum

- Lightweight and weather-resistant: It can resist strong ultraviolet rays, keep it from discoloring for a long time, and has a long service life.

- Good self-cleaning and strong stain resistance: It does not stick to oil, does not stick to water, and prevents pollution.

- Good craftsmanship: Its coating is uniform and colorful.

- Rich shapes: It can be processed into various complex shapes.

- Green and environmentally friendly: It does not contain any harmful substances to human body.

- Good adhesion and flexibility: Its excellent scratch resistance enables it to withstand strong impacts.

- Good flatness: Low requirements on the base surface during construction and good plane stability.

- Easy and fast installation and construction: It is low maintenance and simple to maintain.

Why is it so popular?

Exterior

Its surface has very high gloss and smoothness, and can present an excellent mirror effect when the surface is clean and flat. At the same time, it does not have the shortcomings of a mirror that is fragile and difficult to clean. It is used for applications with relatively high decorative requirements.

Performance

Although it has a mirror effect, it still has the advantages of aluminum plate, such as the weight of aluminum plate is lighter than most materials, self-cleaning, weather resistance, corrosion resistance, water and moisture resistance is stronger, which can effectively improve the quality and reputation of the product.

Application of mirror aluminum

- Lighting reflectors

- Lamp decorations

- Solar heat collecting reflective materials

- Indoor architectural decoration

- Exterior wall decoration

- Household appliance panels

- Electronic product casings

- Furniture kitchens

- Automobile interior

- Exterior decoration

- Signs

- Logos

- Luggage

- Jewelry boxes

How to maintain mirror aluminum plate?

Aluminum products are widely used in our lives, and the chemical substances are extremely stable and not easily corroded. Therefore, many users who use aluminum plates ignore the maintenance of aluminum plates, causing damage to the aluminum plates. Under long-term corrosion, the service life of the aluminum plate will also be affected. Especially for mirror aluminum plates, because the surface is smoother and more beautiful, once it is scratched, it will affect the aesthetics of the aluminum plate. Next, we will introduce the correct cleaning method of mirror aluminum plate.

First, we can use a large amount of water to directly rinse the surface of the mirror aluminum plate.

Second, after basically rinsing away the dirt on the surface, use detergent and focus on cleaning the areas with more serious dirt.

Third, use a large amount of water to rinse away the detergent attached to the mirror aluminum surface.

After such cleaning, the mirror aluminum products will look brand new.

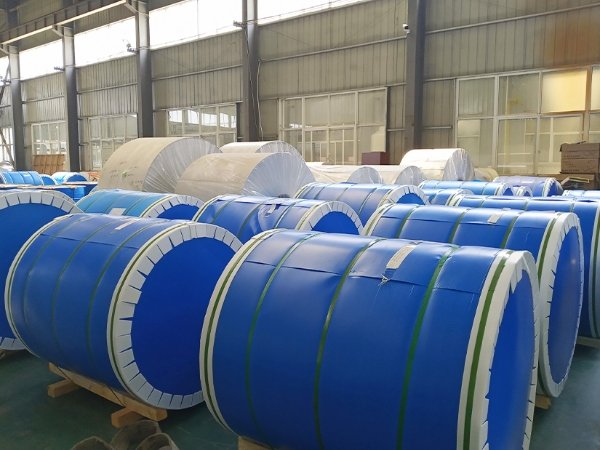

Package

There are two types: coils and plates. Their packaging conforms to international shipping standards, but there are still differences.

Aluminum coil

There are two types of packaging for aluminum coils, one is eye to wall and the other is eye to sky. eye to wall is more common, but it takes up more space and cannot be stacked. eye to sky is more expensive, but can be stacked. A container can hold more goods, which makes it more cost-effective on average.

Aluminum plate

First, use plastic or kraft paper to wrap the aluminum plate, use fumigated wooden pallets or fumigation-free wooden pallets underneath, and finally fix it with steel strips.