Mill finish aluminum refers to the raw, unpolished state of the metal without any treatment or finishing. The metal in this form is largely untreat and often appears somewhat dull in appearance. Raw aluminum undergoes an extrusion process to produce mill finish aluminum without any further processing.

As a result, polished aluminum retains many of the characteristics and properties of cast aluminum, as well as soft spots on the surface. Its natural appearance can vary depending on the exact alloy used in its production and its intended use.

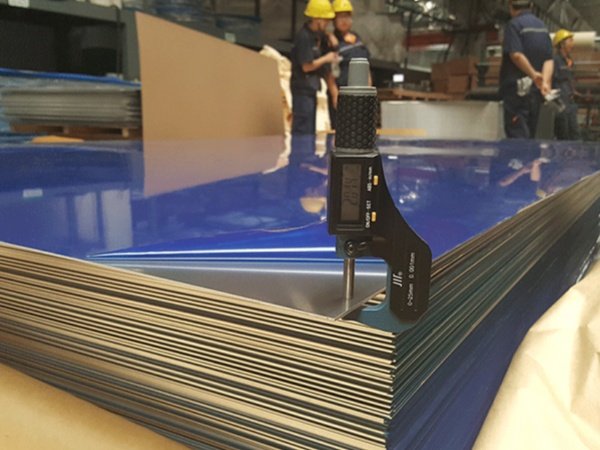

Aluminum sheet has good weather resistance and corrosion resistance. It is composed of aluminum, zinc alloy plating and organic coating, which can effectively prevent erosion from the atmospheric environment and extend its service life. In addition, the construction industry widely uses aluminum sheet, an environmentally friendly material. For exterior wall decoration, roof covering, and interior decoration.

Construction field: Aluminum plates play an important role in the construction industry, mainly used to manufacture curtain wall aluminum plates, decorative plates, aluminum doors and windows, etc.

Transportation field: Manufacturers often use aluminum plates to produce body structural parts, interior. And exterior decorative parts, and more in vehicles such as automobiles, trains, and ships.

Electronic and electrical field: Manufacturers often use aluminum plates to produce parts like housings and radiators for electronic products.

Packaging field: The packaging field widely uses aluminum plates. Aluminum plates play a crucial role in the production of food cans, beverage cans, and other products.

+8613783526689

+8613783526689

Gongyi, Zhengzhou, Henan, China.